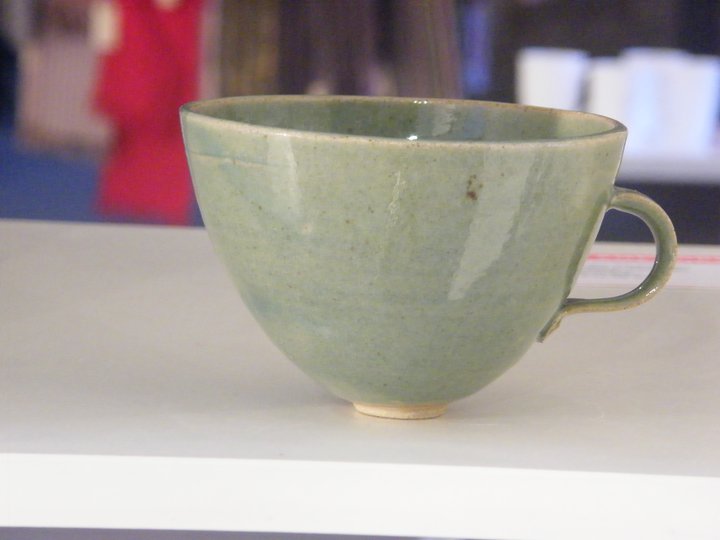

So here is the new film about making Hembury type bowls https://www.youtube.com/watch?v=gnKPTq_SGUw&t=516s

Pageviews last month

Wednesday 13 January 2021

Wednesday 3 June 2020

Wednesday 13 May 2020

Chapter 5 from my dissertation

Chapter 5.

Clays and

soils of Devon.

The sourcing of early southwest Neolithic pottery has depended largely

on identifying inclusions but not the clays. Archaeologists have agreed

generally that local clays would be sourced, not more than 3km, (Gosselain, The

source, accessed on line) for making pots from the site. However, the only

definite way to source clays is to test them through SEM and NAA-Neutron activation

analysis, XRF analysis. These are the normal tests to determine chemical

analyses of clays and archaeological sherds. This produces statistical and

chemical analysis data which is used for a finger print match from samples

taken from sherds, and it has to be considered whether the extra cost of this

type of research is worth the gain in statistical enhancement of the current

state of knowledge. If this information

was available it would be possible to write definitive clay paste recipes for

the Neolithic, not just speculative ones.

The clays and soils are mapped below, in Figs 12 and 13 ((Harries et al

2004 Gallois, 2004) and the maps

are relevant only to the study and prospection areas, of east Devon.

I.

Sampling the clays, quartz and sands.

Appendix II provides a list of the sources of clay and tempers which

were sampled, prior to work starting on the quartz temper project.

Quartz is available within most types of geology of the region. The

quartz used in this project was sourced from The Plym estuary to The River Otter,

at Hams Cottage, Honiton, see Fig.11, and Budleigh Salterton beach and estuary. The

quartz pebbles from Budleigh were very distinctive in their uniform size and

shape, however, and although Budleigh has been cited as the most likely source

(Quinell and Taylor, forthcoming) of

quartz used for pottery from sites in east Devon, pebble beaches are protected

which prevents collection on a large enough scale for a project of this size

when other sources are easily available. Pebble and vein quartz is readily available

on beaches such as Whitsand Bay, nr Plymouth, in the river sands on the River

Otter, Creedy and Yeo. Additionally, vein

quartz is widespread in the environment. It is possible to say that it is found

everywhere. From the samples prospected for the purposes of this project, this

would appear to be the case. A lot of

vein quartz ends-up as river smoothed pebbles of all sizes, both crystalline

and non-crystalline. There are a lot of large, outcrops of crystalline quartz

on Dartmoor both east and west. There are small rounded grains from granite river

sands and Upper Greensand river sands (personal observation). It is also possible to find vein quartz which

contains well-formed crystals.

The geology of the region has featured heavily in this project. The soils and subsoil particularly, not least

for prospecting for good potting clays. As the project has proceeded the geographical

area which should be looked at has increased to include Cornwall. However, when

the focus of the project changed to production

issues where sourcing clays was no longer the focus, the scope and timing of the project have limited the

prospection for Cornish clays within the study area and only small samples of

the east Devon clays have now been collected. I still haven’t managed to find a freely

available source of Permian breccia clay.

The

articles which have been really useful in locating some of these resources are

published by the Ussher Society, Geoscience in the South-West England, which,

among other types of research, run geo-commercial prospecting projects testing

the stability of soils and subsoil in advance of civil engineering works. All

articles are free access and available on online. www.ussher.org.uk. In fact

the Ordnance Survey soil maps have not been referenced as they are not as up to

date now as the Ussher Society proceedings.

The

clays of the Exeter and east Devon region consist generally of the Namurian

clay, which is found all over the region, see Fig 12 above, it is the

weathering product of the shale-slate

beds from the upper carboniferous Crackington formation; as well as the

Devonian red sandstone clays which have not been prospected or used in this project. The Permian breccia, which would probably be

relevant to the Raddon enclosure pottery, formed along a fault in the

Crackington formation in the Permian era which is called the Crediton Trough,

(Harries et al 1995). The Gault or

keuper marl clays which are formed on the Upper Greensand which were sourced at

Branscombe and Monkton, nr Honiton and extend beyond Lyme Regis would, perhaps,

be relevant to the pottery at High peak and Donkey sanctuary.

Fig.11… River Otter at Hams Cottage, Honiton, Devon. Showing the natural

sieving action of sand and gravel on meanders and river banks. Author’s

photograph.

Although

these two clays are very distinct, the Branscombe sample being a much darker

brown, The Monkton Greensand sample is likely to be the same clay type as that

found three kilometres away at Hembury Fort, see fig 13 below,. Hembury is covered in the exact same clay (personal

observation, Todd, 1984)) and both

these clays are weathered in situ. Both

clays are extremely sticky and would likely make goodpotting clays. Initial plasticity tests for these clays was positive. With levigation and sieving, their plasticity can be increased but it

is not definitively possible to say anything about the potential of clay

until it has been fired to temperatures of 800˚, 1000˚,1150˚, 1280˚ Celsius. These are the traditional

temperatures used to determine at which temperature clay matures and if it

melts at any of these temperatures, it is not possible to use beyond that

temperature and thus limits the potential of the clay.

Fig. 12. Geology of east Devon. Showing the major geological formations

and nomenclature. This is the source for naming the yellow clay used in

experiments as Namurian. (Harries et al 2004)

Subscribe to:

Posts (Atom)